Loading...

information

Nothing can compare to the rich warm glow of gold and for thousands of years, man has been prospecting for it, trading in it, and making fine jewellery from it. In its natural state, it is too soft to fashion into jewellery, but by alloying it with other harder metals, it is possible to increase its strength and durability.

Gold fineness is measured as parts per thousand by weight, or in carat weight. Pure gold is expressed as 24 carats, i.e., 100% fine. 18 carat gold is 75% fine, and 9 carat gold is 37.5% fine. 9 carat gold is the lowest alloy allowed to be legally described as gold. 9 carat is harder than 18 carat gold, and less expensive, but the colour is not as rich as that of 18 carat.

The colour of gold can be varied by the addition of various metals to form an alloy. Most 18 carat yellow gold is made up of 75% by weight fine gold, 12% copper, and 12.5 % silver. Rose gold, sometimes known as pink or red gold, and in the nineteenth century as Russian gold, is achieved by alloying 75% by weight fine gold with 15% copper and 10% silver. The greater the proportion of copper to gold and silver, the deeper the colour. White gold is produced by alloying fine gold with silver, nickel, palladium, and zinc.

The goldsmiths of eighteenth-century France were masters in the craft of combining coloured gold to produce a refined and elegant effect in fine jewellery and small objets d’art. It was Carl Faberge who studied the work of the French masters from previous centuries and revived the technique of carving multi-coloured gold ornamentations.

English silver has been held in high esteem for centuries. In 1275, a statute of King Edward I decreed that the silver used for the coinage of the realm should consist of 11 troy ounces and 2 ¼ pennyweights of pure silver to the troy pound, being the modern-day equivalent of 92.5% by weight. This alloy became known as Sterling Silver. This strict quality of English silver has been carefully monitored by the Worshipful Company of Goldsmiths and Silversmiths since its establishment in 1327.

The high lustre and shine of polished silver is timelessly beautiful, and due to the metal’s malleability, can be produced as a variety of decorative objects and jewellery. Sterling silver is typically alloyed with 7.5% copper by weight. Nickel may be introduced to strengthen the silver to make it hard enough to manufacture silverware and items of jewellery.

In contrast to the traditional Sterling silver (92.5%), Britannia silver is an alloy of 11 ½ troy ounces to the pound, that is, 95.833% pure silver alloyed with copper. Britannia silver was introduced in 1697 in order to protect the currency of the realm from silver coins being clipped or melted as a source of silver for manufacture as silver manufactured from the lower standard coinage would no longer meet the newly introduced Britannia standard. In addition, the Britannia standard would allow for the export of English silver to France in the seventeenth and eighteenth centuries, as sterling silver was below the legal standard for silver in France. After complaints from the silver trade about the softness of Britannia silver, sterling silver was once again authorised for use by silversmiths in 1720. Britannia silver is still often used for commissions relating to historical events.

Although platinum was discovered in Europe in the sixteenth century and used in small amounts, it wasn’t until the late nineteenth century that the perfect alloy for platinum was discovered. Platinum in its natural state is too soft a metal to be used for the fabrication of jewellery. However, with the addition of copper and palladium, usually up to 5% by weight, an extremely hard alloy is created. After the discovery of this alloy, demand for platinum as a material for jewellery surged during the Edwardian and Art Deco periods, as the strength of platinum was perfect for creating delicate yet strong jewellery designs. The addition of small amounts of cobalt produces a platinum alloy with good casting qualities, whilst tiny amounts gallium and indium introduce springiness to the metal.

Palladium came into use as an alternative to platinum for jewellery in 1939 due to the advent of the Second World War when the latter became a strategic resource. Naturally white, palladium, unlike white gold, does not require rhodium plating. Palladium is not as commonly used as white gold or platinum due to the difficulty of casting the metal. Palladium in the United Kingdom is hallmarked as three standard alloys of 500, 950, or 999 parts of palladium per thousand of the alloy.

The Goldsmiths Company was founded in 1327 in London by royal decree to regulate the quality of precious metals in England. The process of hallmarking precious metal goods grew out of this need for protecting consumers.

A hallmark is a set of component marks applied to articles of the precious metals gold, silver, platinum or palladium. It means that the article has been independently tested by the Goldsmith’s Company and it guarantees that the metal conforms to all legal standards of purity. All precious metal products made in the United Kingdom must be, by law, hallmarked by this set of marks to ensure quality.

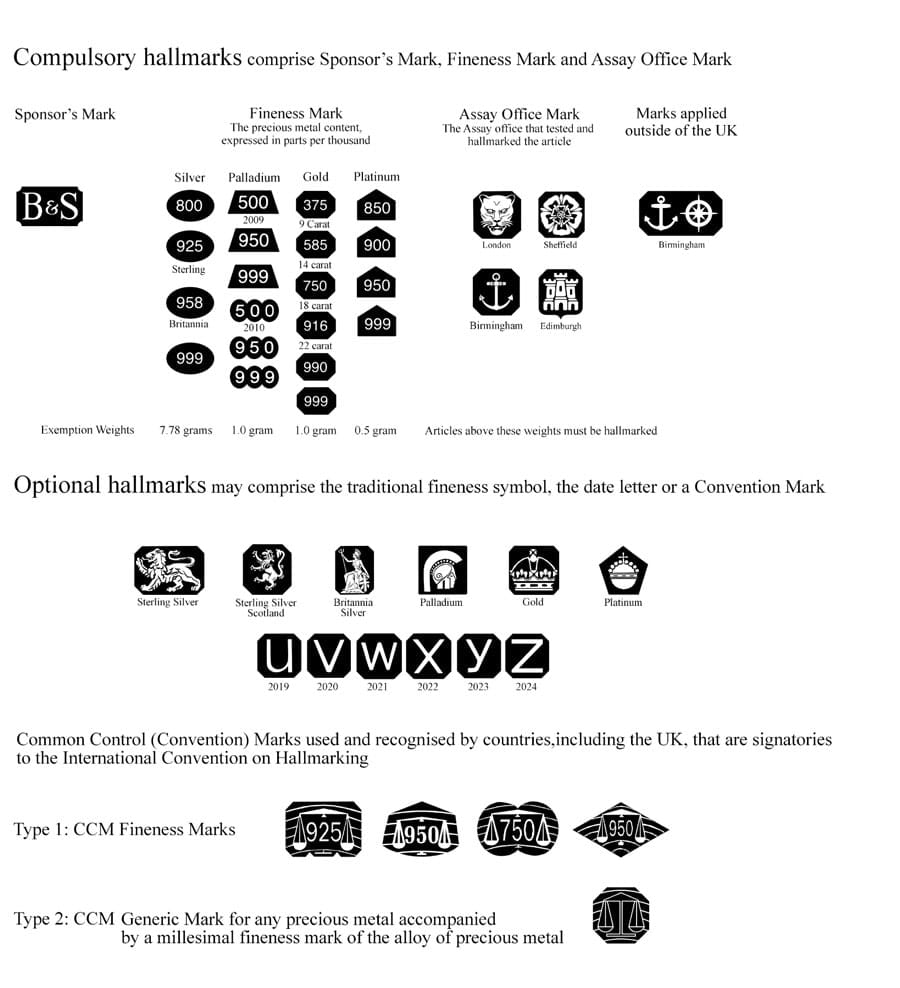

The Full Traditional Hallmark comprises five marks. The Sponsor’s Mark is the registered mark of the company or person that submitted the article for hallmarking, and replaces what was formerly known as the Maker’s Mark. The Traditional Fineness Mark is a historical symbol which indicates that the precious metal is of a minimum legal standard. The Millesimal Fineness Mark indicates how fine the metal is, and by the shape of the shield, indicates the precious metal type. This numerical format was made compulsory in 1999 and shows the precious metal content of the article, expressed in parts per thousand. The Assay Office mark indicates which Assay Office the precious metal was hallmarked in. The Date Letter mark, expressed alphabetically, indicates the year in which the precious metal was hallmarked.

Today only the Sponsor’s Mark, the Finesse Mark and Assay Office Mark are compulsory, but at Bentley & Skinner we have chosen that every piece we manufacture should bear the full five traditional hallmarks.

Bentley & Skinner’s unique Sponsor Mark can be recognized by the B&S symbol within a scalloped cornered cartouche. This hallmark represents the long history of Bentley & Skinner, as Bentley’s origins began with the London Refining & Metallurgical Works established in Clerkenwell Road in 1905. This hallmark is a symbol of assurance that the piece of metal has passed the quality assurance of both the Goldsmiths Company and Bentley & Skinner whose manager Paul Greer is a freeman of the Worshipful Company of Goldsmiths.

For information on the Worshipful Company of Goldsmith’s hallmarking policy, please click here.

Today, shoppers expect the jewellery they wear to be made responsibly and with a respect for human rights and the planet. Sadly, the process of extracting and refining gold can be devastating for communities and for the planet, involving child labour, dangerous working conditions, pollution, and deforestation. It has been estimated that to produce one brand new gold wedding ring almost twenty tons of waste is generated.

At Bentley & Skinner, we take these issues very seriously. Most of the gold that we use in our manufacture is recycled, which is the most sustainable form of gold available. In this way, old gold jewellery and scrap gold is melted down, refined, and rolled into sheet or wire ready for re-use in our workshops. Of the small amount of new gold that we need to purchase from our suppliers, most comes through Tanaka Precious Metals, a global group who have rigorous and far-reaching sustainability policies. Click here to view Tanaka’s sustainability policy.

Responsible sourcing of gold is not merely a matter of compliance: it is a reflection of the values we uphold, our commitment to ethical and environmental practices, and the way that we have chosen to practice our business. We ensure that the precious metals we use come from legal and ethical sources that have not been associated with illegal activities, crime, armed conflict, or human rights abuse. Our suppliers collaborate with the Swiss Better Gold Association, which improves supply chains for gold from Artisanal and Small scale Mines (ASMs) as well as improving the situation of the ASM miner.

We take our responsibility towards the environment very seriously. Click here for our environmental and social policy.